Let’s Discuss Your Project!

We partner with a diverse range of customers, including startups, resellers, and designers, all striving to elevate their businesses to new heights. Our mission is to provide the support they need to thrive and grow successfully.

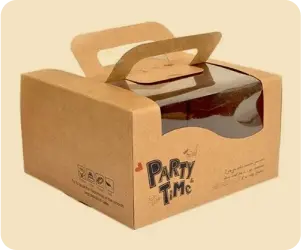

Providing more in your Customized Packaging Solution to give your packaging the more Unique Look and Premium Quality.

Fully customized structures tailored to your specifications.

Versatile options for a variety of applications to keep products intact.

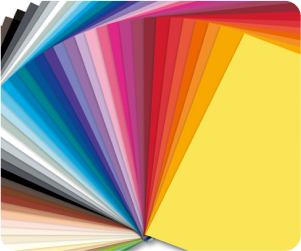

Unlimited selection of textured and colored paper.

Meet your exact needs and preferences with easily personalized handles and buttons.

Meticulously crafted premium custom leather and wooden boxes.

Wide selection of custom luxurious ribbons for you to choose from.

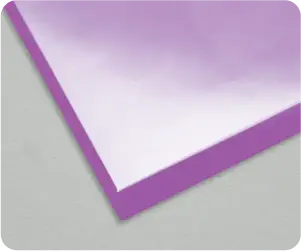

Thin layer that gives the box a glossy surface.

Thin film that gives the box a matte surface.

Thin film providing a smooth touch and velvety surface

Water-based coating that creates a soft semi-gloss surface.

UV-cured ink allowing for spot and flood applications.

Inexpensive option that coats and adds surface protection.

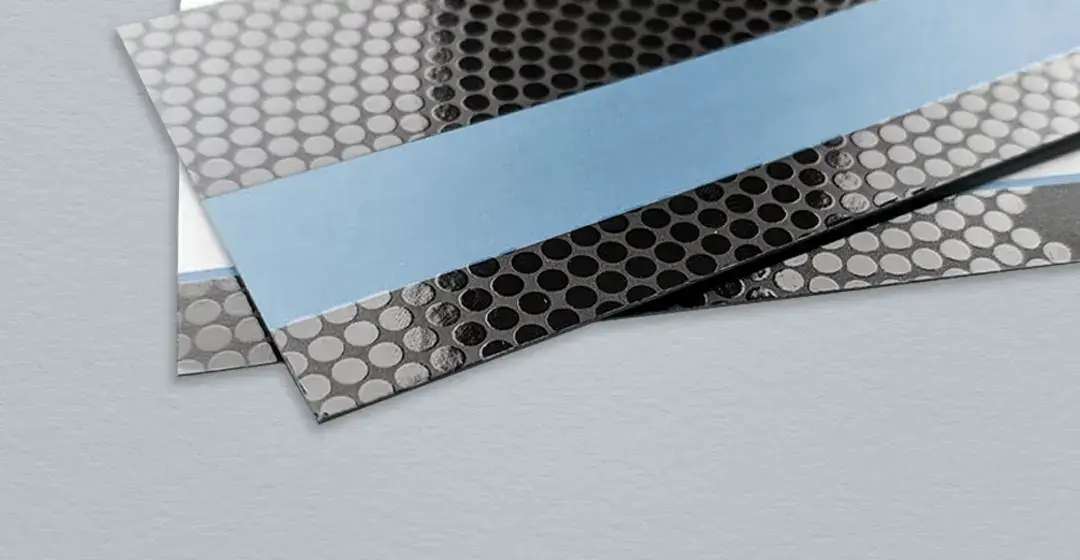

Add an extra metallic sheen to your box surface.

Give your surface extra decorative shimmer and shine.

Ink coating that produces smooth surface. Cheaper alternative to lamination.

Ink coating that protects the interior of the box for food-safe applications.

Heat transferred foil onto paper surface.

UV gloss coating cured on specific areas.

Special process that creates a raised or recessed pattern on the surface.

Special technique with a transparent plastic film covering the cut-out.

Special process where a cut-out is created on the packaging surface.

We have been serving different industries across the US and Canada for the past 15 years. Our successful track record is evidence of our commitment to quality. We ensure that the preferences and budgets of our clients remain aligned. We offer magnetic closure rigid boxes at affordable wholesale prices across the US and Canada. Our seasoned team is there to guide you using their expertise in the packaging industry. You can get free of cost consultancy related to choosing the suitable material, design, and shapes of the your desired boxes. With our fastest turnaround, you will get your order on time.

Our catalog is filled with innovative designs of custom packaging boxes; you can explore them and find the suitable one for your desired purpose. We use premium material to produce these boxes therefore, you can make amendments in the design till you find a dream model of magnetic box.

Get a free quote today, and let’s start our packaging journey together!

We do not bind our customers to specific materials; instead, we give them the freedom to choose the right one according to their preferences. If they need a magnetic box for a luxury item, so we offer them rigid and cardboard material. These materials provide the best protection alongside a luxury appearance that leaves a lasting impression. Rigid and cardboard also allow for the addition of premium finishes that make these boxes a perfect fusion of functionality and style.

We also craft magnetic closure boxes in fully recyclable kraft material that expresses your brand's commitment to sustainability in style.

We offer a diverse range of finishing options, including gloss lamination that brings a shiny spark and matte lamination for a sleek look. The list doesn't end here because we also offer unique finishing options to enhance the visual appearance of your brand’s logo and information. It includes embossing, debossing, spot UV, foil stamping and many other. These top-notch options can make your products stand out among the rest.

If looking for a custom packaging solution at best market prices for your high-end products, then look no further then CustomBoxesHub.com as we are offering bespoke custom printed magnetic closure rigid boxes at wholesale rates. We ensure our premium packaging solutions are accessible for all kinds of business therefore, we offer best market rates. With free shipping, free 3D mock templates, and free consultancy, you can save a lot of money and get massive benefits. We always put our customers first, and for that, we follow their preferences and specifications to reach the final result.

To place an order or ask questions, you can contact us at (866)-472-5540 any time between 9 am and 6 pm or email us at info@customboxeshub.com.

We supply more than custom boxes. We specialize in customer experience! Apart from our personalized packaging solutions, we also offer free services to increase value!

We provide customized packaging boxes in custom shapes and sizes to meet your branding needs.

We manufacture custom-printed boxes according to your preferred shapes and sizes.

The minimum quantity you can expect from us is 50 Boxes ( Hardproof Sample Option Available ).

We manufacture packaging boxes in PMS and CMYK color schemes. We also offer discreet printing..

10pt to 28pt (60lb to 400lb) eco-friendly Kraft, e-flute corrugated, bux board, cardstock.

From eco-friendly packaging to luxury boxes, we've got everything you need to take your product to the next level. And with our fastest turnaround time, you won't have to wait long to get started.